Technical Data

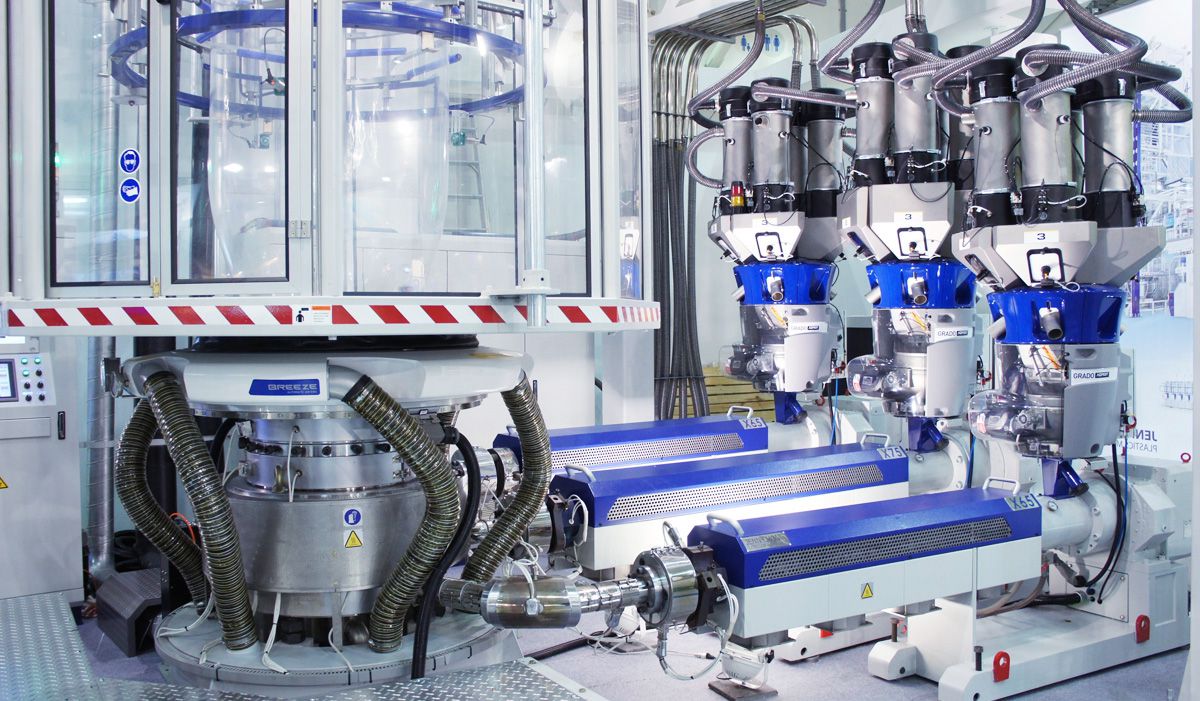

| MODEL | Co-Extrusion Layers | Applicable Materials | Screw Diameters* (mm) | Film Layflat Width* (mm) | Film Thickness* (mm) | Extrusion Capacity* (kg/hr) |

|---|---|---|---|---|---|---|

| JC-3CX1100 | 2 / 3* / 5 | LDPE / LLDPE / MDPE / HDPE / PP / EVA | 50 / 55 / 50 | 1000 | 0.025 - 0.25 | 220 |

| JC-3CX1500 | 2 / 3* / 5 | LDPE / LLDPE / MDPE / HDPE / PP / EVA | 55 / 65 / 55 | 1400 | 0.025 - 0.25 | 320 |

| JC-3CX1800 | 2 / 3* / 5 | LDPE / LLDPE / MDPE / HDPE / PP / EVA | 65 / 75 / 65 | 1700 | 0.025 - 0.25 | 450 |

| JC-3CX2300 | 2 / 3* / 5 | LDPE / LLDPE / MDPE / HDPE / PP / EVA | 75 / 90 / 75 | 2200 | 0.025 - 0.25 | 550 |

|

* The film layflat widths and thicknesses, extrusion capacities, and screw diameters listed in this table are for our standard JC-3CX three-layer blown film co-extrusion lines. Our two- and five-layer blown film co-extrusion lines are highly-customized to meet customer specifications and do not have standard arrangements. |

Application

Agricultural Film

Industrial Film

Shrink Film

Barrier Film

Express Bag

Innovative solutions for your business.

Monofilament

Meltblown

Blown Film

Raffia Tape & Twine

Monofilament

Strapping Band

Others

No. 90, Nanpi Rd., Nanxin Vil.,

Taibao City, Chiayi County 61251, Taiwan

Phone: +886 5 2376175

E-Mail: [email protected]

Taibao City, Chiayi County 61251, Taiwan

Phone: +886 5 2376175

E-Mail: [email protected]

Products