PET Monofilament : Properties, Applications, and Manufacturing Efficiency

Polyethylene terephthalate (PET) monofilament is rapidly transforming industries with its balance of strength, durability, and environmental performance. As a trusted solution across agriculture, filtration, sports, and industrial textiles, PET monofilament yarn offers unmatched mechanical properties and manufacturing advantages—especially when paired with advanced extrusion technology.

Whether you’re optimizing your current production or exploring new material possibilities, this guide reveals why PET monofilament is the material of choice for modern, high-efficiency manufacturing. For a deeper understanding of the production process, refer to our Comprehensive Guide to Monofilament Extrusion Process.

Application for PET monofilament

Unlike multifilament fibers, PET monofilament maintains its cylindrical structure, offering greater tensile strength, rigidity, and dimensional stability.

It is available in various forms, including :

- PET monofilament yarn for weaving and knitting applications

- Bristles for brushes and industrial cleaning tools

- High-rigidity monofilament for fencing, conveyor belts, and 3D printing

PET outperforms in long-term outdoor durability, structural consistency, and recyclability—making it the preferred choice for industries seeking sustainability and reliability.

Key Properties of PET Monofilament

Mechanical Performance

- High tensile strength ensures load-bearing capabilities in demanding applications like fencing and belts.

- Low elongation prevents material deformation and maintains structural integrity.

- Excellent rigidity supports dimensional accuracy in stretched and tensioned systems.

- Compression and bending resistance enhances performance in wear-prone environments.

Chemical and Environmental Resistance

- Superior UV resistance enables stable outdoor use without degradation.

- Excellent chemical resistance allows safe operation in acidic, oily, or alkali-rich conditions.

- Abrasion resistance extends product lifespan in mechanical friction zones.

- Hydrolysis and flame-retardant options available for high-risk industrial environments.

Thermal and Dimensional Stability

- Low shrinkage supports consistent processing and minimizes yield loss.

- Stable under high-speed manufacturing conditions, maintaining roundness and filament uniformity.

Industrial Applications of PET Monofilament

Agriculture and Fencing

PET monofilament is up to 80% lighter than traditional steel wires, yet strong enough for demanding agricultural setups. It's widely used in :

- Greenhouse structures and trellis systems

- Insect and anti-hail netting

- Animal fencing and barrier mesh

Key advantages :

- Corrosion-free performance

- Easy installation and low maintenance

-

UV and weather resistance

Filtration Systems

PET monofilament is engineered for high-precision mesh fabrics and filtration products used in :

- Water treatment and wastewater systems

- Dust collection

- Industrial air and fluid filtration

It offers :

- High tenacity and dimensional consistency

- Excellent chemical compatibility

- Long operational lifespan in harsh environments

Sports and Footwear

In athletic applications, PET monofilament yarn delivers structure, breathability, and recyclability for :

- Shoe uppers and soles

- Sports mesh and insoles

- Reinforced woven fabrics

Its transparency and customizability also support fashion-forward and sustainable design.

Conveyor Belts and Industrial Textiles

PET monofilament’s mechanical resilience makes it ideal for:

- Conveyor belts and treadmill belts

- Hook-and-loop fasteners

- Selvedge yarns and spacer fabrics

- High-performance sewing threads

It reduces noise, improves tracking, and outlasts metal or nylon-based alternatives. To explore current trends in monofilament yarn production machinery, see our article on Monofilament Yarn Making Machine : 4 Trends.

Bristles and Yarn-Based Applications

- PET bristle monofilaments used in household, industrial, and personal care brushes

-

PET monofilament yarn woven into precision textiles, technical fabrics

How PET Monofilament Supports Smooth and Efficient Manufacturing

PET monofilament isn’t just strong and durable—it’s also easy to work with. Its smooth processing behavior means it can be produced consistently at high speeds, helping manufacturers save time and reduce waste.

Whether it’s being shaped into yarn, extruded into bristles, or formed into high-tensile strands, PET flows well through machines and responds reliably to heat and stretching. This leads to:

- Fewer interruptions during production

- More consistent product quality

- Lower maintenance needs for machinery

Its ability to maintain shape, strength, and smooth texture during manufacturing makes it a smart choice for companies looking to improve both efficiency and product reliability.

And when paired with the right extrusion equipment, like PLASCO’s precision-engineered systems, PET monofilament becomes even more efficient to produce—offering long-term value and smoother operations for manufacturers.

Why PET Monofilament Is the Future of High-Performance Industrial Materials

With its combination of strength, stability, and sustainability, PET monofilament stands at the forefront of innovation in modern manufacturing. Compared to alternatives like nylon or metal wires, it offers:

- Lower weight and higher processability

- Resistance to degradation in harsh environments

- Compatibility with automated, high-speed production lines

- Potential for closed-loop recycling with rPET

PET monofilament is not just a material—it’s a solution for companies pursuing efficiency, durability, and environmental responsibility.

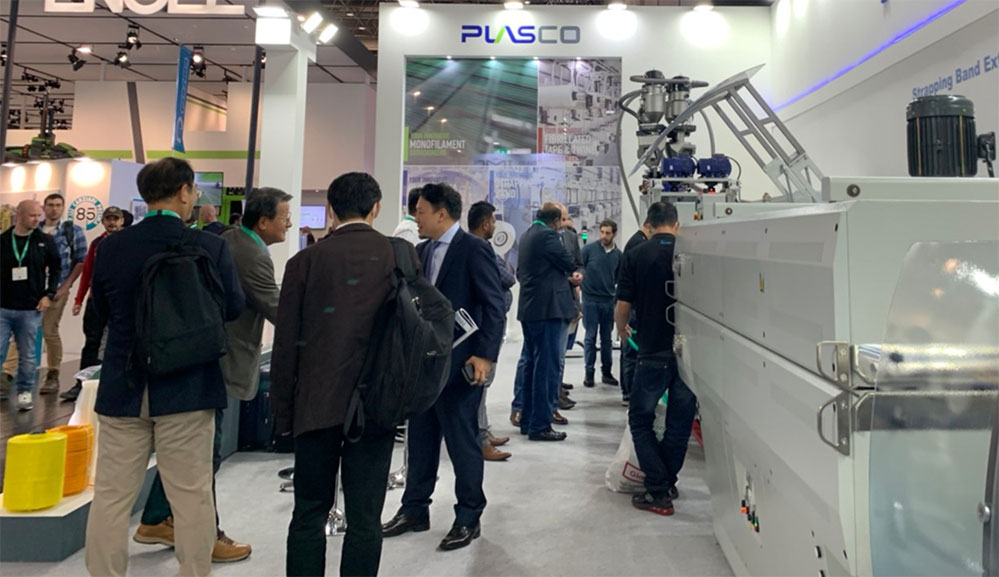

Optimize Your PET Monofilament Production with PLASCO

At PLASCO, we specialize in developing high-precision monofilament extrusion lines tailored to your performance goals. Our equipment is trusted by manufacturers worldwide for its efficiency, reliability, and adaptability.

Our Advantages:

- Precision-controlled extrusion systems for uniform filament output

- Energy-saving design for reduced production costs

- Customizable configurations to meet various filament sizes and strengths

- Automation-ready systems for consistent quality and labor efficiency

- Comprehensive technical support from installation to optimization

Ready to upgrade your PET monofilament production capabilities?

Contact PLASCO today for a personalized consultation and discover how our solutions can help you stay ahead in a competitive global market.

Taibao City, Chiayi County 61251, Taiwan

Phone: +886 5 2376175

E-Mail: [email protected]